|

Silicon Investigations Vacuum Tube Research and Custom Scientific Equipment Services

Vacuum tube technology has largely been relegated to the

history books. About the only applications where current vacuum tube

technology is still in use are in niche markets where tubes still out perform

solid state devices. Some examples are high power transmitting tubes

(power amplifiers, traveling wave tubes, magnetrons [microwave ovens], high

power switch tubes [thyratrons], and some specialty light sources like deuterium

lamps). There are, however, some cutting edge technologies where vacuum

tube science is being revisited to solve long standing roadblocks.

One such device is known as a vacuum transistor. This novel device

has the potential to operate in the THz (terahertz) frequency range where

conventional silicon semiconductor transistors can't go beyond the low GHz frequency

range.

Another area where advances are being made is in the cathode design. In

traditional tubes, the cathode is heated by a filament to the point where

it emits electrons by thermal emission. This is why tubes draw so much

power, like a conventional light bulb. We are working on materials

that can emit electrons without being heated to incandescence, thus making

them more efficient. One such material is diamond like carbon (DLC),

which is a thin film of diamond deposited on a metallic substrate. DLC

has the potential to emit electrons without the high filament temperature needed for

conventional tubes.

We have a long history of building custom scientific apparatus for industry

and academia. Some examples of devices we have designed and constructed

are high voltage/current switching tubes (the krytron is one example), custom

light sources for raman spectrography and cryogenically cooled detector assemblies,

just to name a few.

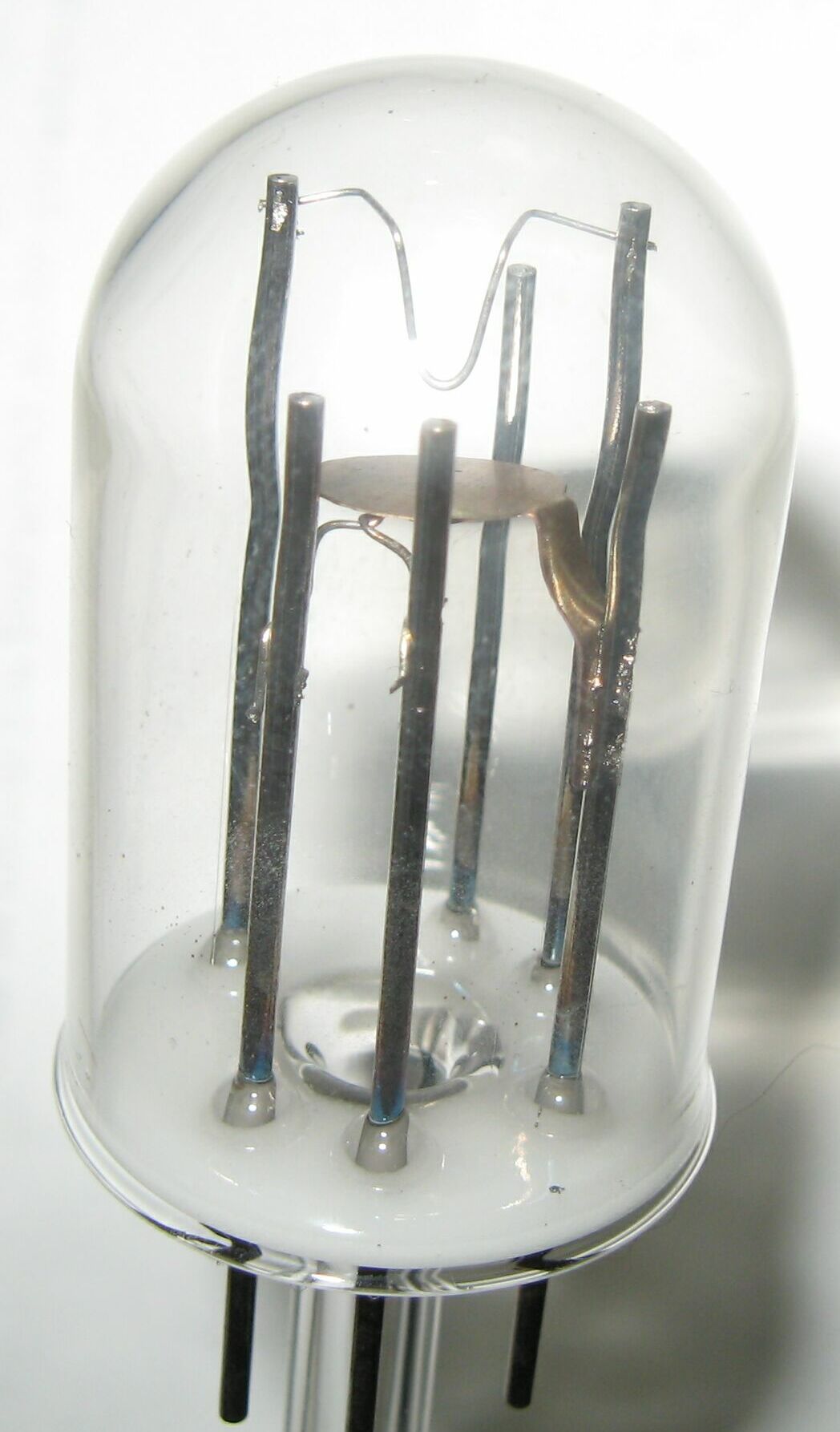

Shown below are some research tubes we have developed to test new cathodes.

Cathode demonstration tube before evacuation.

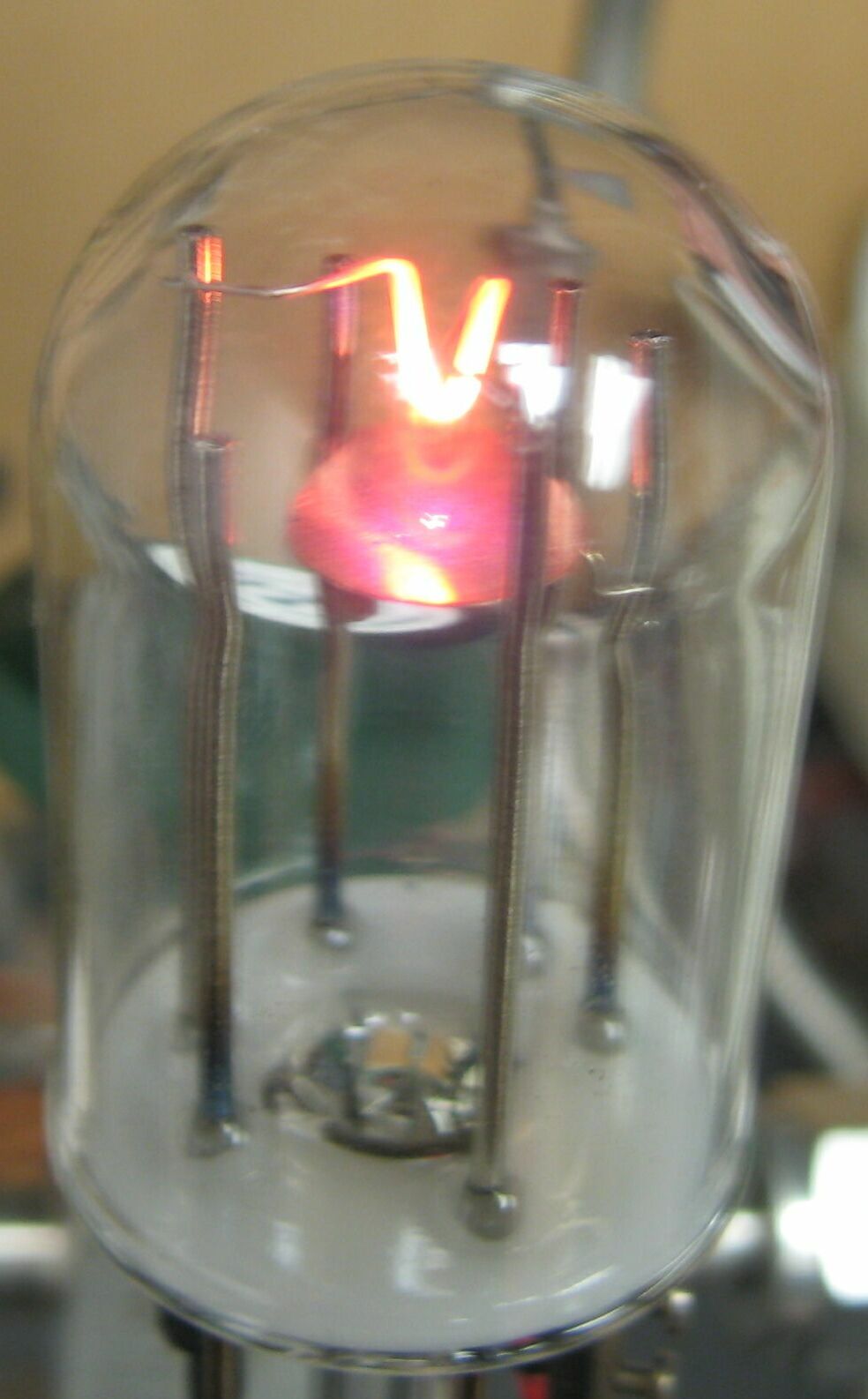

Tube being evacuated while being heated with a IR laser beam to bake out contaminants.

Tube with low pressure diamond like carbon being grown

on the cathode. The bright spot is where the methane/hydrogen plasma

is depositing diamond like carbon on the cathode.

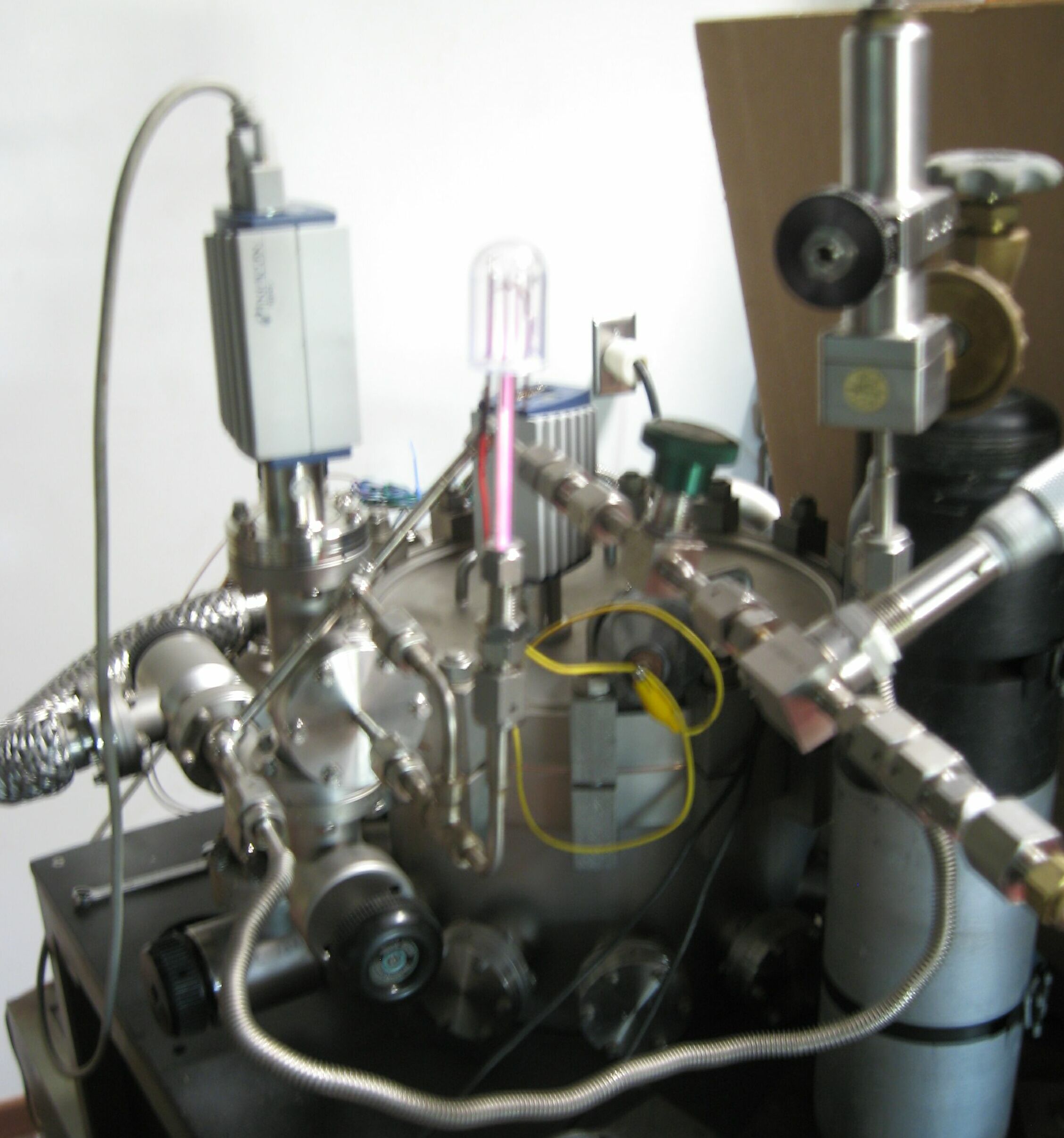

Vacuum

pumping station used to evacuate tubes and then back fill with the active

gas mixtures, as needed. We can provide tubes fully evacuated or with

custom gas mixes suitable to your needs, including argon, neon, krypton,

xenon, helium, and mixes of gasses. We can also add trace amounts of

mercury to gas filled tubes to promote long cold cathode life span.

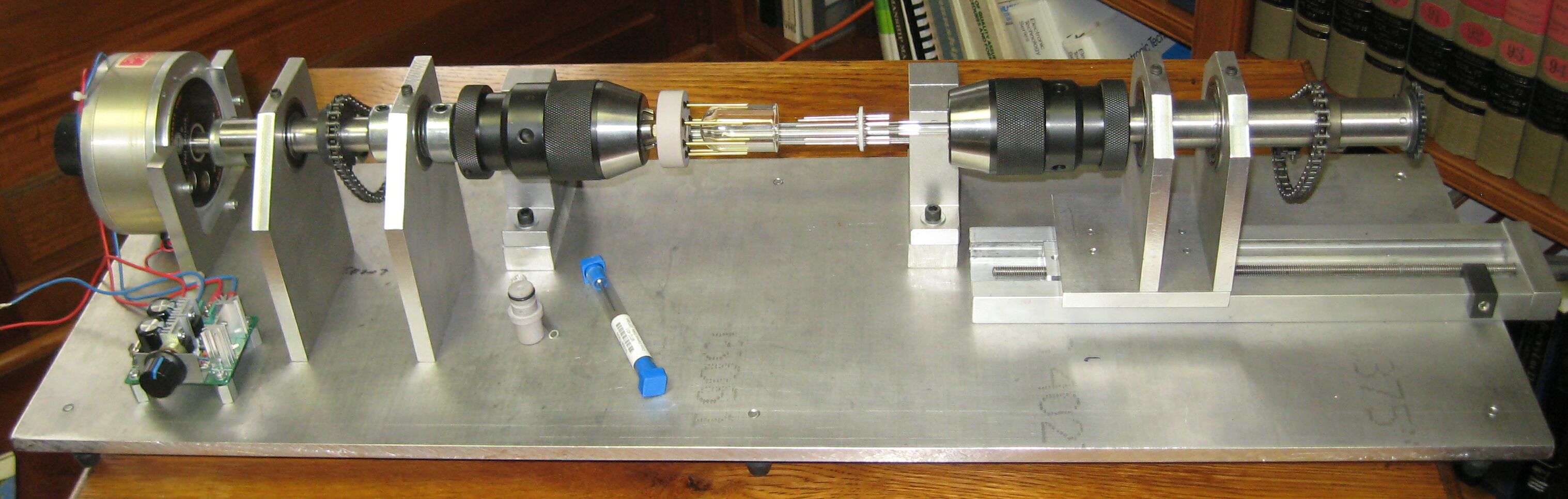

Custom glass lathe used for vacuum tube construction and sealing. Both

the headstock and tailstock are driven synchronously to maintain registration

between the two tube parts.

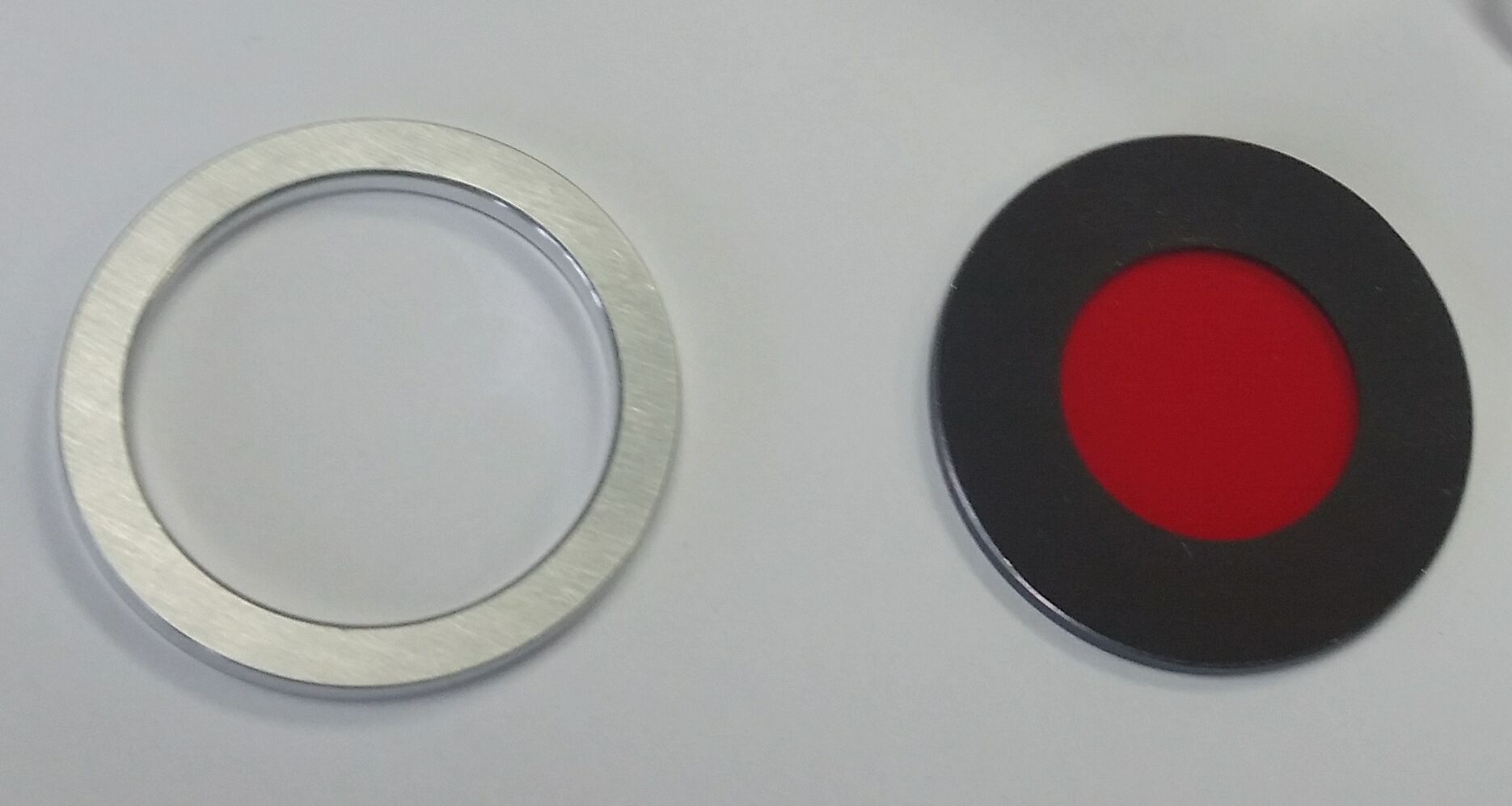

Shown above are the spacer ring and optical filter for a

custom spectral tube prototype. The red filter has 13nm of chromium

coated around the perimeter.

The above image shows the assembled lamp

on the vacuum pumping station. The tube is then evacuated and back filled

with a neon gas mix to a pressure of 2.5 torr.

Above, the tube has been evacuated and

back filled with the neon mix and is running. The red spot projected

out of the top of the tube has the spectral properties needed for the project.

If you have any questions or would like to discuss a potential application

of our technology, please feel free to contact us.

Please

call us at 920-955-3693 or email [email protected]

|